Horizontal Directional Drilling (HDD) falls under the wide spectrum of Trenchless Technology for the installation of underground services with minimum excavation.

HDD can be used for the installation of Water pipes, Sewer pipes, storm water pipes, optic fibre sleeves and electrical cables sleeves.

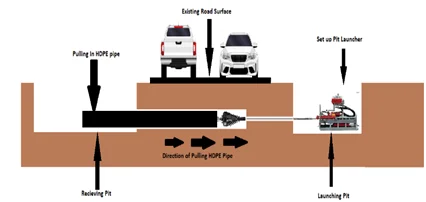

HDD machinery used thrust and rotational force to drill a directed horizontal bore. The drilled bore (pilot hole) is enlarged to the required bore diameter through a process called back reaming.

Properly planned and executed, HDD can reduce the unwanted surface disturbance caused during underground service by 80 to 90%.

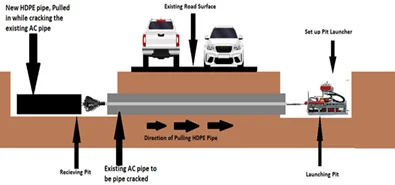

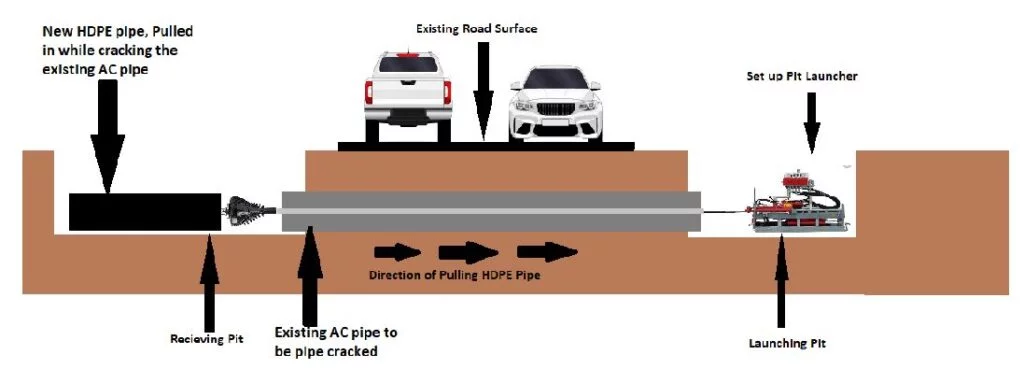

Pipe cracking or pipe bursting falls under the wide spectrum of Trenchless Technology for the replacement or old worn-out underground pipelines.

As the name suggest “pipe cracking” process is done by cracking or bursting the old worn-out sewer or water pipe while pulling in a new butt-welded HDPE pipe in its place.

The new butt-welded HDPE pipe then takes the slope, depth, and position of the worn out, cracked pipe.

The newly installed buttwelded HDPE pipe can be the same diameter as the pipe being replaces, this is not as size to size pipe cracking. The new HDPE pipe can also be larger in diameter than the worn-out pipe being replaced, this is known as upsizing

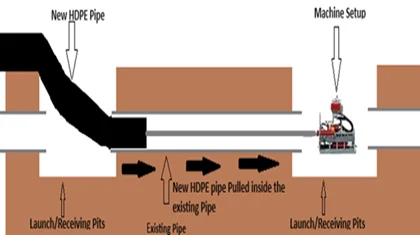

Sliplining Is also another method of Trenchless Technology pipe rehabilitation. Unlike in pipe cracking or Horizontal Directional Drilling- The Newly installed Butt-welded HDPE pipes is always smaller in diameter than the old worn-out Steel, Concrete, or plastic pipeline.

Sliplining process is done by pulling in a newly butt-welded HDPE pipe inside an existing worn-out pipe, The new HDPE pipe becomes the new carrying pipe or product pipe. The space between the worn-out pipe and the new HDPE pipe is then grouted with cement and sand mixture by pumping.

The pulling in of the new HDPE pipe inside the existing pipe is done by rods of a drill rig or a winch.

Most Trenchless Technology construction methods uses HDPE pipes, Butt welding of HDPE pipes therefore is most necessary.

Butt welding is a method of fusing together HDPE pipes to a continuous desired length. The fusing is done by heating both ends of the HDPE pipe by what is called a “heating plate”. After both ends are heated to a desired melting temperature they are then pressed or fused together using pneumatic or hydraulic force.

We also do Electrofusion of HDPE pipes for all HDPE fittings and HDPE pipe jointing mechanism.

Why Go-Trenchless!?

So Why Trench when you can Go-Trenchless….!?

The construction of new infrastructure by the conventional means of bulk excavation disturbs the environment by damaging surface services such as Roads, Buildings, Natural landscape aesthetics and traffic disturbance which increases a threat to the health and safety of the public.

we strive to deliver superior quality services that exceed expectations, contributing positively to the development and advancement of the communities we serve.

Important Links

info@brezobrezo.co.za

+27(0) 72 713 3629

42 Krakow Street Cosmo City Ext. 7 City of Johannesburg 2188 South Africa

© 2024 brezo-brezo | Powered by instapostercreations

we strive to deliver superior quality services that exceed expectations, contributing positively to the development and advancement of the communities we serve.

Important Links

info@brezobrezo.co.za

+27(0) 72 713 3629

42 Krakow Street Cosmo City Ext. 7 City of Johannesburg 2188 South Africa

© 2024 brezo-brezo | Powered by instapostercreations